Performance Details

The use of self-tapping inserts has significant advantages over pre-tapped holes, moulded-in inserts and wire thread inserts. They eliminate close tolerance holes required for tapping directly into the base material, damaged tools and low productivity resulting from moulded-in inserts and the time consuming process of placing wire thread inserts into pre-tapped holes. The use of a self-tapping insert can result in a reduction in thread size required because of the insert’s large effective shear surface saving material and reducing cost and weight.

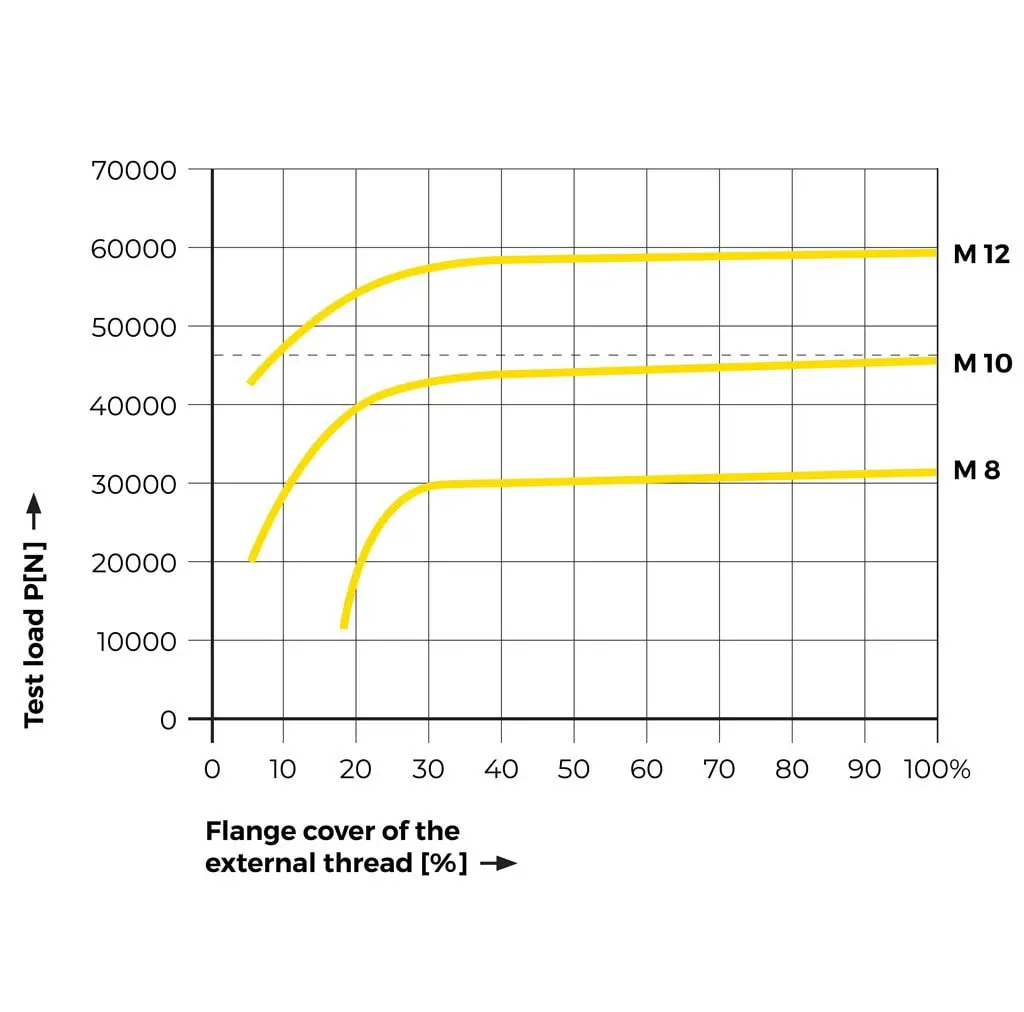

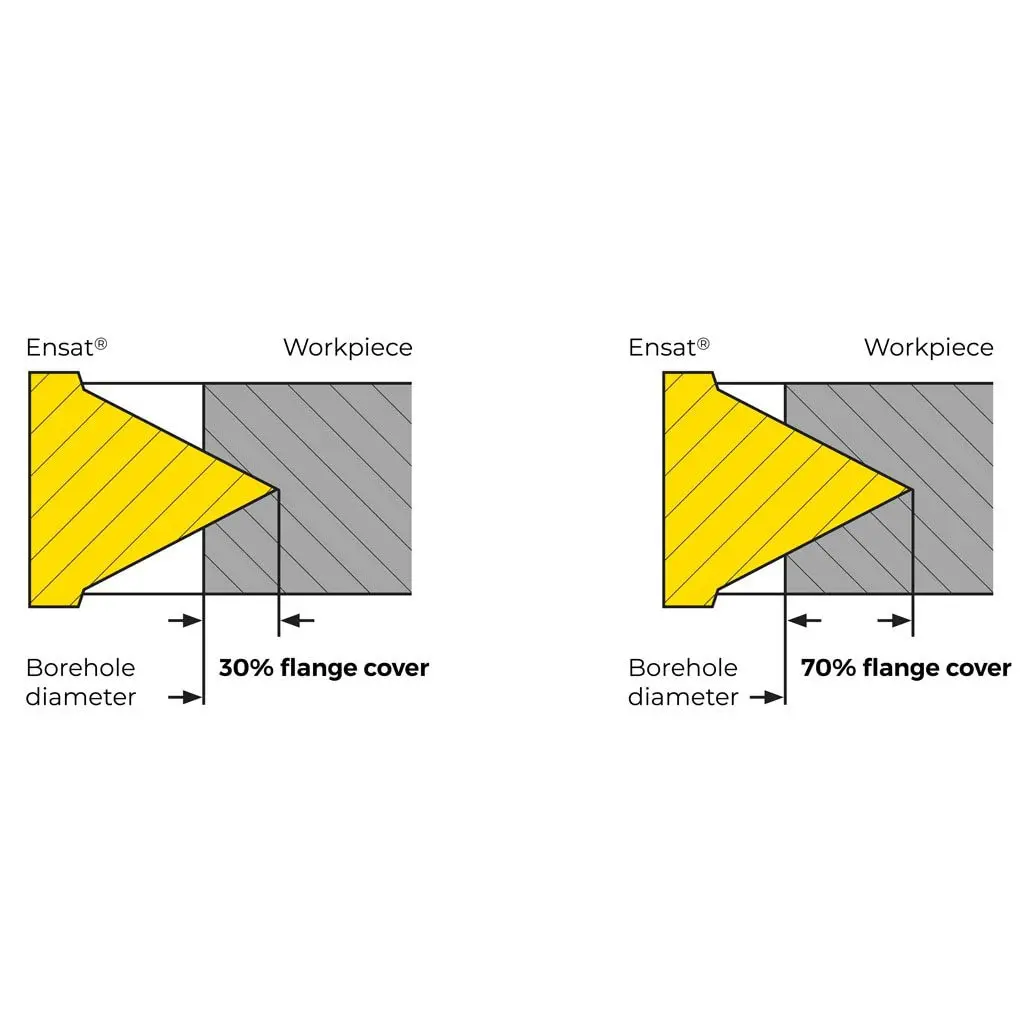

External Thread Interference

For a work-piece made of a light alloy, this diagram illustrates clearly that whilst correct hole sizes are important for product reliability, the self-tapping insert 302 achieves almost maximum pull-out with only 30% external thread interference.

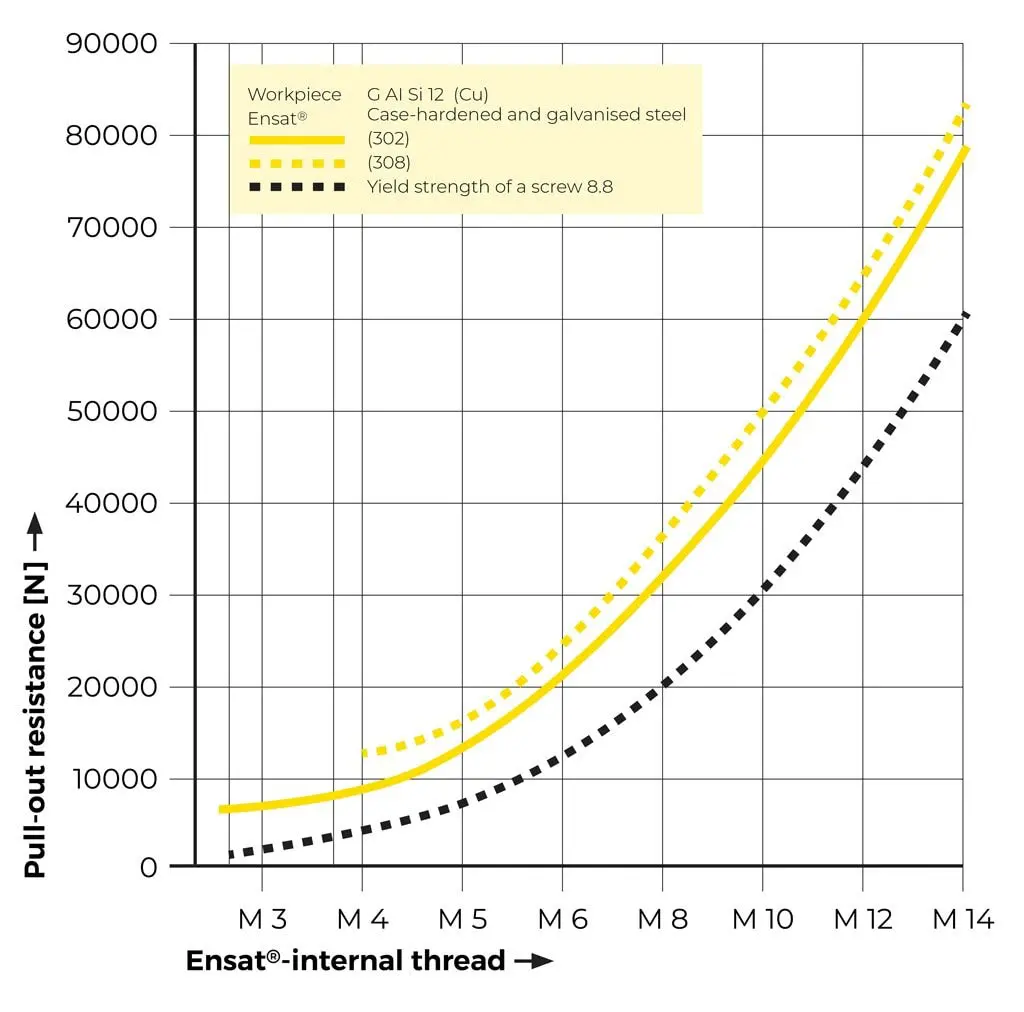

Pullout Resistance

In light alloy, the self-tapping steel insert resists a pullout force in excess of the yield point of an 8.8 grade bolt.

O tẹle ẹrọ China

O tẹle ẹrọ China

WeChat

Ṣayẹwo koodu QR pẹlu WeChat