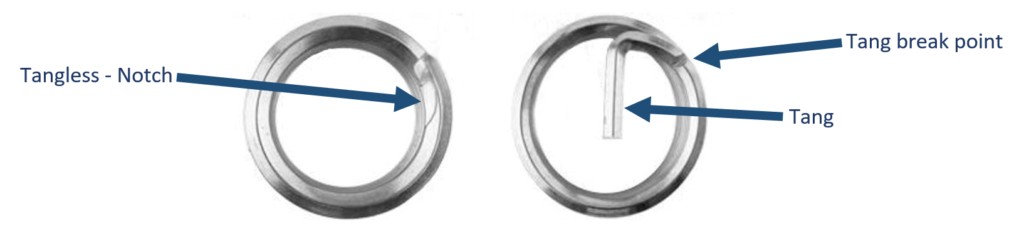

Tang and tangless inserts are both types of threaded inserts used in various industries, such as aerospace, automotive, and electronics, to provide strong and durable threads in materials like metal, plastic, or composites. In fact, Tangless CoilThread inserts are virtually identical to tanged inserts in all aspects, except for their method of installation and removal.The key difference between them lies in the presence or absence of a tang (a small protruding tab) used during the installation process:

Tang Inserts:

1.Tang inserts have a small tab or tang at the bottom or top of the insert, depending on the design.

2.During installation, the tang is engaged with a special installation tool (commonly called a tang break-off tool or tang break-off pin) that is threaded into the insert.

3.As the tool is turned, it applies torque to the tang, causing it to break off cleanly at a predetermined point within the insert.

4.Breaking off the tang leaves the threaded portion of the insert securely embedded in the material, creating a reliable and strong threaded connection.

Tangless Inserts:

1.Tangless inserts, as the name suggests, do not have a tang.

2.Instead of a tang, they have other methods for installation, which can vary depending on the specific design. Some tangless inserts use a helical coil structure, while others may have other flanges or other features to facilitate installation.

3.The absence of a tang means there is no need for a tang break-off tool, simplifying the installation process.

4.Tangless inserts are often preferred in applications where the presence of a tang could be a concern, such as in electronics, where it might interfere with other components.

In summary, both tang and tangless inserts serve the same fundamental purpose of providing strong threaded connections in materials, but they differ in their installation methods. Tang inserts require the use of a tang break-off tool, while tangless inserts have alternative installation mechanisms and are preferred in situations where the presence of a tang is problematic. The choice between them depends on the specific requirements of the application and the materials being used.

Sriegių įdėklai Kinijos gamintojas

Sriegių įdėklai Kinijos gamintojas

"WeChat"

Nuskaitykite QR kodą naudodami "wechat".