Keenserts, also known as key-locking inserts or solid inserts, are a type of threaded insert used in the field of thread repair. Keenserts are designed to provide a strong and durable thread reinforcement or repair solution for various applications. Here are some key applications of keenserts in the thread repair field:

1. Automotive Repair:

Keenserts are commonly used in automotive repair to restore damaged or stripped threads in engine components, such as cylinder heads, engine blocks, and exhaust manifolds. They provide a reliable and long-lasting repair solution, avoiding the need for expensive part replacements.

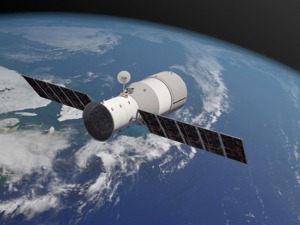

2. Aerospace Maintenance and Repair:

In the aerospace industry, where safety and reliability are paramount, keenserts are employed for thread repair in critical components of aircraft and spacecraft. They help restore the integrity of threaded connections in components like engine housings, landing gear, and structural elements.

3. Industrial Machinery Repair:

Keenserts are used to repair damaged threads on industrial machinery, including hydraulic systems, conveyor systems, and production equipment. These inserts help extend the operational lifespan of machinery and prevent costly downtime.

4. Construction Equipment Repair:

Construction equipment, such as bulldozers, cranes, and excavators, often requires thread repair due to the challenging conditions they operate in. Keenserts are used to restore threads in components like hydraulic cylinders, structural elements, and fasteners.

5. Oil and Gas Industry Maintenance:

The oil and gas sector relies on keenserts for thread repair on equipment, such as wellhead components, valves, and pipelines. These inserts help ensure the reliability and safety of threaded connections in this industry.

6. Maritime Equipment Repair:

Keenserts are applied in the repair of maritime equipment, including ships and offshore platforms. They are used to restore threads on components such as ship engines, propellers, and winches.

7. Railway Maintenance:

8. Keenserts are used in railway maintenance to repair threads on various components, such as rail tracks, signaling systems, and rolling stock, ensuring the safe and reliable operation of railway infrastructure.

9. Mining Equipment Repair:

Mining equipment often faces severe wear and tear. Keenserts are used in the repair of threads on components like drill rigs, conveyor systems, and crushers to ensure efficient and safe operation.

10. Utilities and Power Generation Repair:

Keenserts are applied in the repair of threaded connections in power generation equipment, such as turbines, generators, and transformers, as well as utility infrastructure like power lines and transmission towers.

11.General Maintenance and Repair:

Keenserts are used for general maintenance and repair tasks across a wide range of industries. They help restore damaged threads in components, reducing downtime and equipment replacement costs.

Keenserts are known for their strength and resistance to vibration and torque, making them a dependable choice for thread repair applications in various industries. They provide a robust solution for restoring and reinforcing threads, ensuring the continued operation of equipment and machinery.

Xov Ntxig Suav Chaw Tsim Tshuaj

Xov Ntxig Suav Chaw Tsim Tshuaj

Tus kheej

Luam theej duab QR Code nrog Wechat