Performance Details

The use of self-tapping inserts has significant advantages over pre-tapped holes, inserts moulés et inserts filetés. Ils éliminent les trous de tolérance serrés nécessaires pour tarauder directement dans le matériau de base, damaged tools and low productivity resulting from moulded-in inserts and the time consuming process of placing wire thread inserts into pre-tapped holes. The use of a self-tapping insert can result in a reduction in thread size required because of the insert’s large effective shear surface saving material and reducing cost and weight.

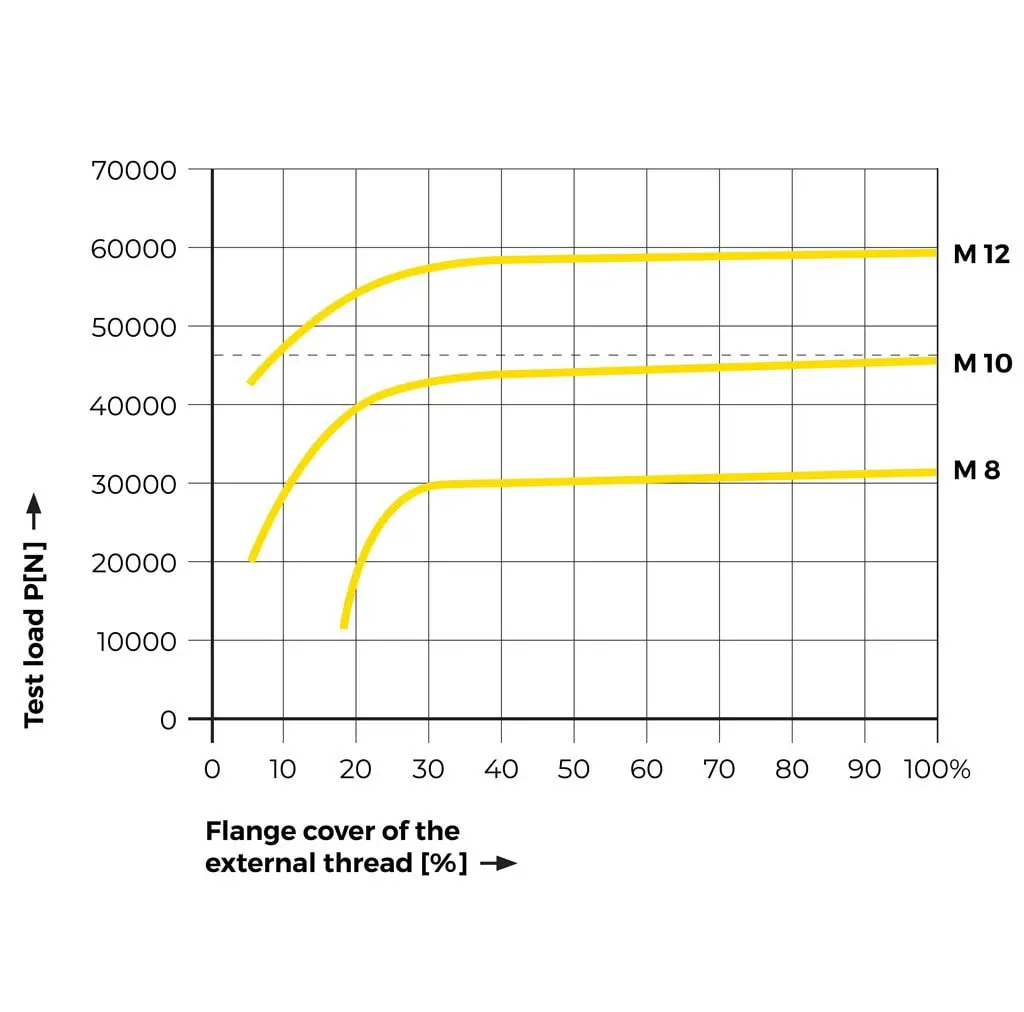

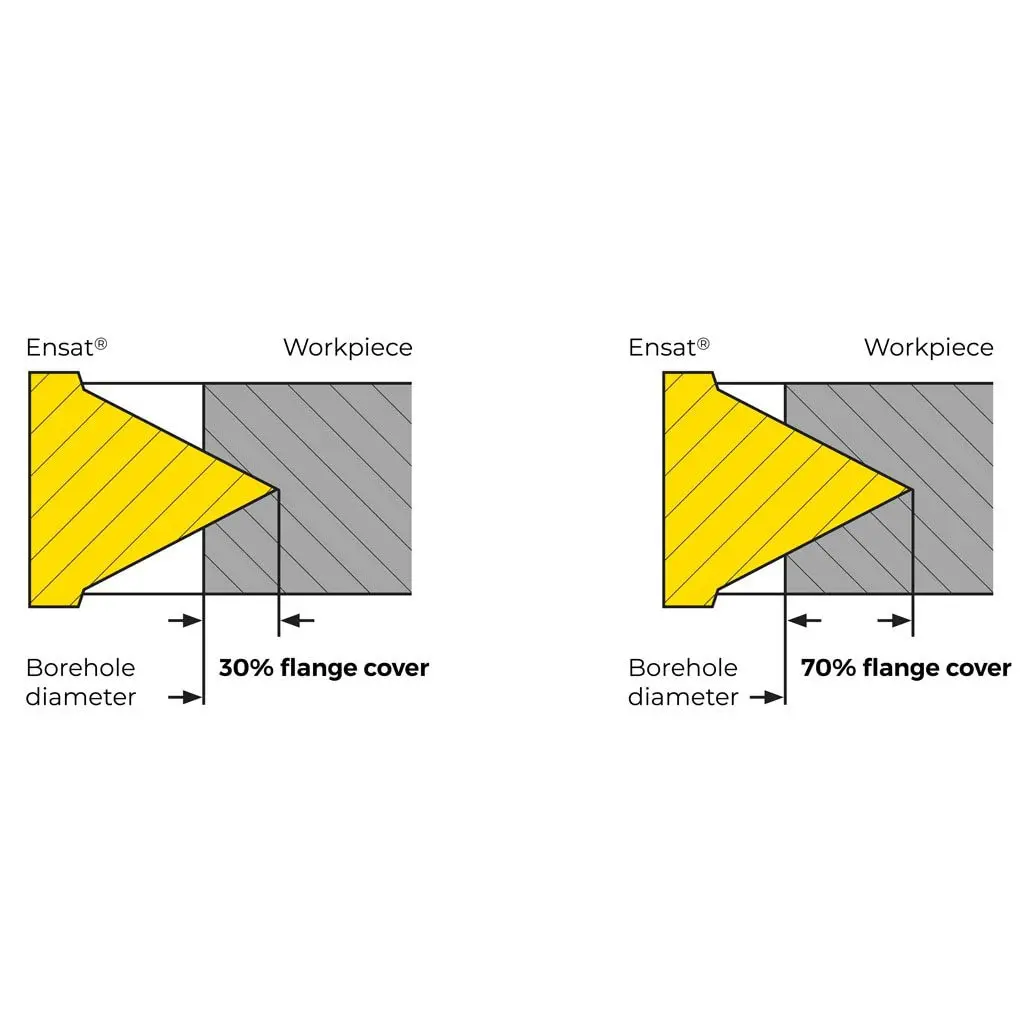

External Thread Interference

For a work-piece made of a light alloy, this diagram illustrates clearly that whilst correct hole sizes are important for product reliability, the self-tapping insert 302 achieves almost maximum pull-out with only 30% external thread interference.

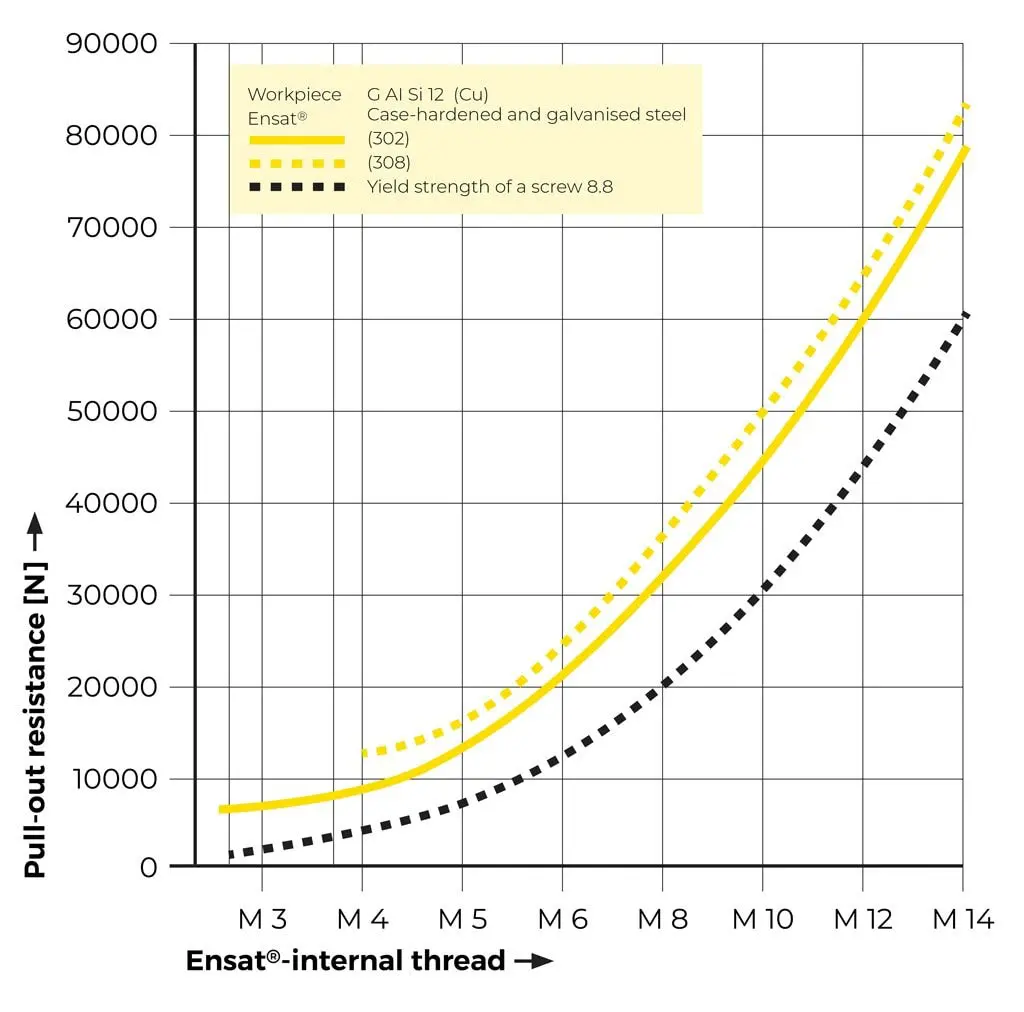

Pullout Resistance

In light alloy, the self-tapping steel insert resists a pullout force in excess of the yield point of an 8.8 grade bolt.

Chine Inserts filetés Fabricants

Chine Inserts filetés Fabricants

WeChat

Scannez le QR Code avec wechat